My Store

CRYOCUT® NEAT L

CRYOCUT® NEAT L

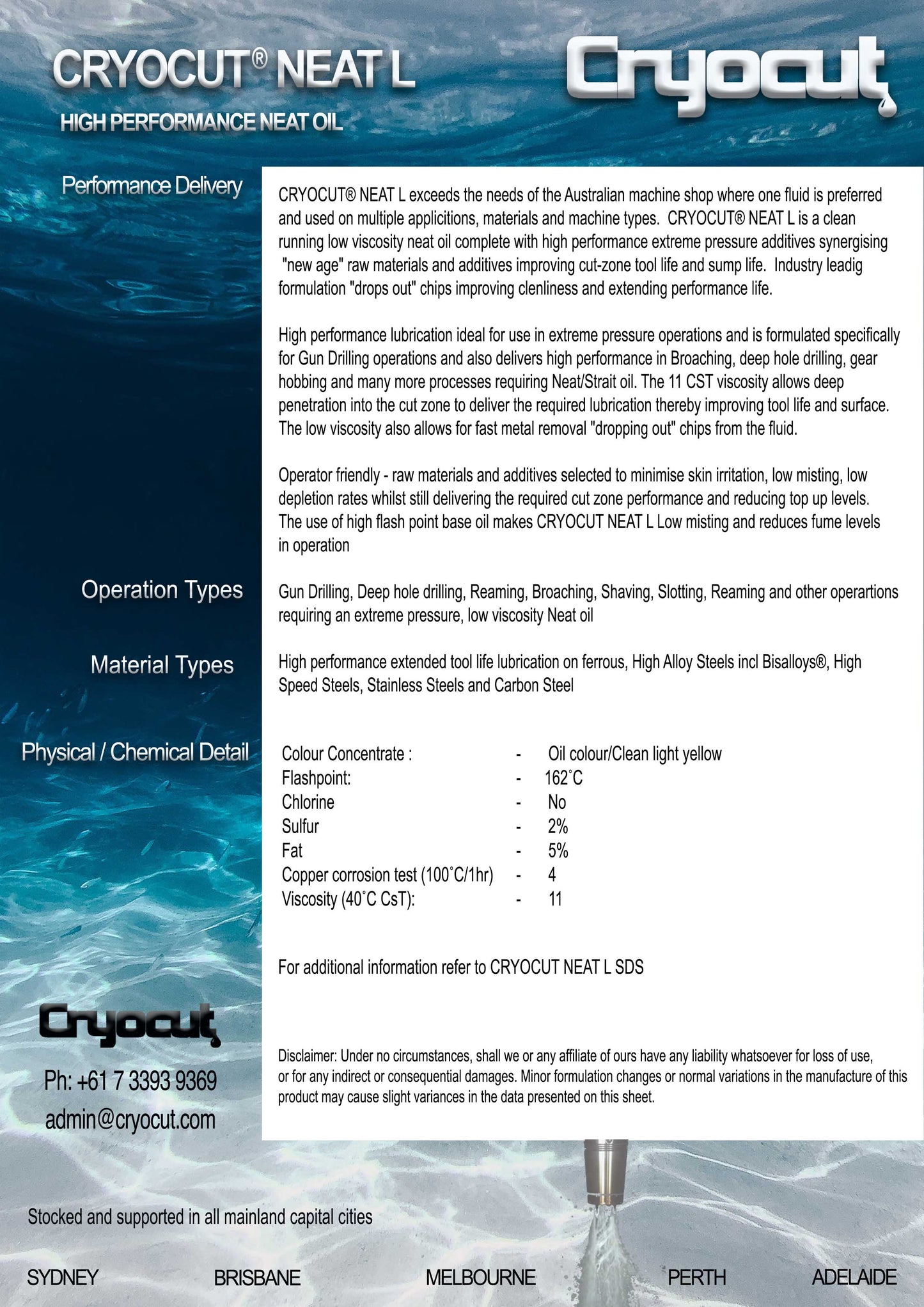

CRYOCUT® NEAT L exceeds the needs of the Australian machine shop where one fluid is preferred and used on multiple applicitions, materials and machine types. CRYOCUT® NEAT L is a clean running low viscosity neat oil complete with high performance extreme pressure additives synergising "new age" raw materials and additives improving cut-zone tool life and sump life. Industry leading formulation "drops out" chips improving clenliness and extending performance life.

High performance lubrication ideal for use in extreme pressure operations and is formulated specifically for Gun Drilling operations and also delivers high performance in Broaching, deep hole drilling, gear hobbing and many more processes requiring Neat/Strait oil. The 11 CST viscosity allows deep penetration into the cut zone to deliver the required lubrication thereby improving tool life and surface. The low viscosity also allows for fast metal removal "dropping out" chips from the fluid.

Operator friendly - raw materials and additives selected to minimise skin irritation, low misting, low depletion rates whilst still delivering the required cut zone performance and reducing top up levels. The use of high flash point base oil makes CRYOCUT® NEAT L Low misting and reduces fume levels in operation.

Gun Drilling, Deep hole drilling, Reaming, Broaching, Shaving, Slotting, Reaming and other operations requiring an extreme pressure, low viscosity Neat oil

High performance extended tool life lubrication on ferrous, High Alloy Steels incl Bisalloys®, High Speed Steels, Stainless Steels and Carbon Steel

For additional information refer to CRYOCUT NEAT L SDS

Disclaimer: Under no circumstances, shall we or any affiliate of ours have any liability whatsoever for loss of use, or for any indirect or consequential damages. Minor formulation changes or normal variations in the manufacture of this product may cause slight variances in the data presented on this sheet.

Share